As industries evolve and adapt to new technologies, the selection of essential components such as valves becomes increasingly critical. The Three Way Ball Valve, a versatile and reliable option for fluid control, is expected to see heightened demand in various sectors by 2025. According to a recent market analysis from Research and Markets, the global valve market is projected to reach $77 billion by 2025, with significant growth in the oil and gas, water treatment, and chemical processing industries. This growth underscores the importance of selecting the right valve for specific applications to ensure efficiency and safety.

Factors such as material composition, pressure ratings, and operation methods play a significant role in determining the best fit for industrial needs. As such, understanding the intricacies involved in selecting a Three Way Ball Valve is paramount for industry professionals aiming to optimize their systems and meet the emerging challenges of the market.

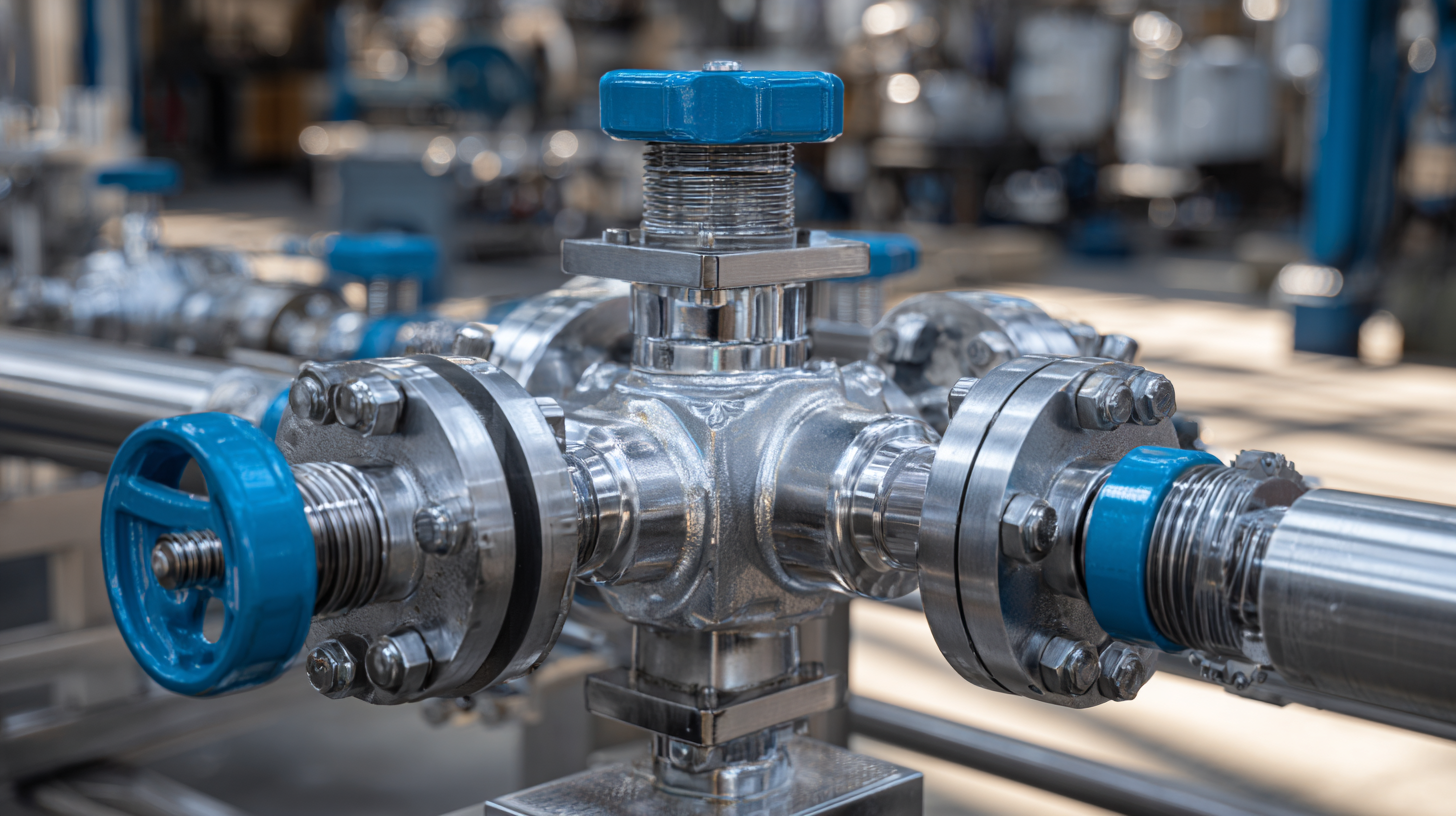

When selecting a three-way ball valve for industrial applications, understanding the various types available is crucial. Three-way ball valves can be categorized primarily into two designs: L-port and T-port configurations. The L-port valve is designed to route the flow between two outlet ports, making it ideal for diverting flow in different directions. Conversely, the T-port valve allows for more versatile flow interactions, enabling mixing or diverting of fluids through all three ports. This diversity in design caters to different operational needs, whether it involves directing flow or blending materials.

Another important consideration is the valve's operational method, which can be either manual or automated. Automated three-way ball valves offer enhanced control and consistency, particularly in systems requiring precise flow regulation. Factors such as material compatibility, pressure ratings, and size must also be evaluated to ensure the chosen valve suits the specific demands of the application. By understanding these distinctions, industries can make informed decisions that enhance operational efficiency and reliability in their processes.

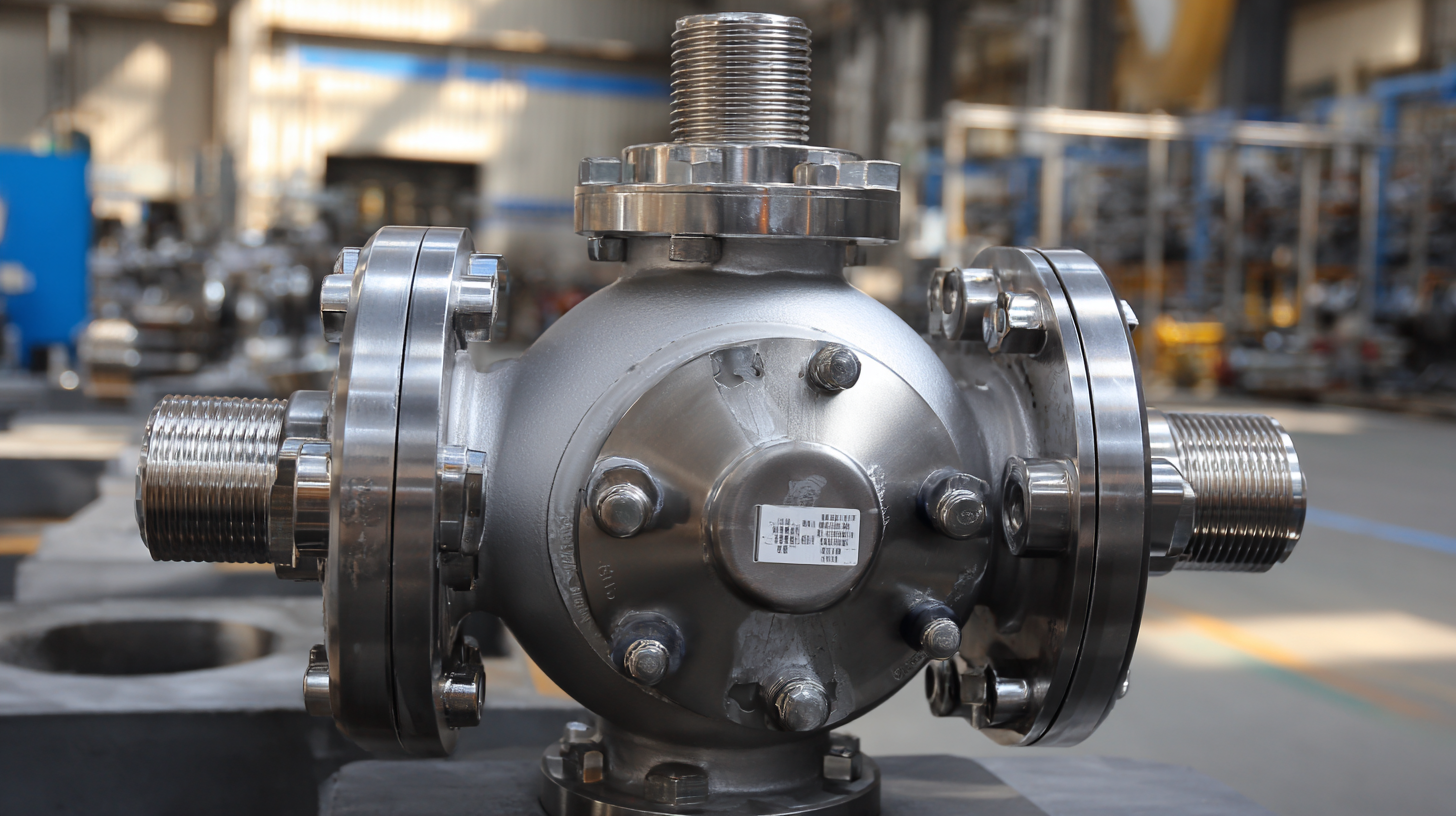

When selecting a three-way ball valve for your industrial applications, several critical factors come into play. First, consider the valve's construction material, which should be compatible with the fluids being handled. Common materials include stainless steel, carbon steel, and PVC, each suited to different chemical properties and temperature ranges. A thorough understanding of the operating conditions can help you choose a valve that will maintain integrity and performance over time.

Another important aspect to evaluate is the valve’s size and flow capacity. The required size will depend on the system’s specifications and the flow rates needed for efficient operation. Additionally, examine the valve's actuation method, whether manual or automated, to ensure it aligns with your operational needs. Finally, look into the valve's maintenance requirements and its ability to provide reliable sealing under varying pressures, as these features significantly influence long-term operational efficiency.

When selecting a three-way ball valve for industrial applications, the choice of material is paramount. The most commonly used materials for ball valves include stainless steel, brass, and PVC, each offering unique advantages suited for specific environments. Stainless steel is particularly favored for its corrosion resistance and strength, making it ideal for harsh conditions and high-pressure applications. It is also suitable for industries such as oil and gas, chemical processing, and water treatment.

On the other hand, brass valves provide excellent reliability and are generally more cost-effective, making them a great choice for moderate pressure and temperature applications. These valves are widely used in plumbing and HVAC systems. For applications involving aggressive chemicals or high temperatures, PVC valves are often preferred due to their lightweight, cost-efficiency, and resistance to corrosion. However, their use is limited to lower-pressure conditions. Ultimately, the decision should consider factors such as temperature, pressure, fluid type, and the specific requirements of the industrial application to ensure optimal performance and longevity.

When selecting a three-way ball valve for industrial applications, understanding its common uses across various sectors can significantly impact the choice. Three-way ball valves are versatile components commonly used in industries such as oil and gas, chemical processing, and water treatment. These valves enable the control and diversion of fluid flow through multiple pathways, making them essential for systems that require efficient flow management. For instance, in the oil and gas industry, they facilitate the switching of flow lines and manage pressure in high-demand environments.

Innovation in valve technology is also shaping the future of three-way ball valves. The projected growth of the global industrial valve market suggests an increasing emphasis on enhanced durability and efficiency. New materials and designs, such as ceramic core ball valves, are being introduced to meet the demands of high-pressure applications. As industries evolve and automation expands, the need for advanced valve solutions will continue to grow, driving the development of three-way ball valves that can adapt to changing operational requirements and regulatory standards, particularly in sectors like food processing where hygiene is paramount.

When it comes to ensuring the longevity of your three-way ball valve, proper maintenance is key. Regular inspections should be conducted to check for any signs of wear or damage. Look for leaks around the valve, as these can indicate issues that need immediate attention. It's also vital to observe the valve's operation, ensuring it opens and closes smoothly without any unusual noises.

Another essential tip is to keep the valve clean and free of debris. Build-up from particles can cause blockages and affect performance. You can easily clean the valve using a soft cloth and, if necessary, a mild detergent. Additionally, lubricating the valve at the recommended intervals helps maintain its function and prevents corrosion over time. Always refer to the manufacturer's guidelines for the best lubrication products and schedules tailored to your specific application.

Lastly, monitoring the operating conditions is crucial for maintaining a three-way ball valve's integrity. Ensure that the pressure and temperature levels are within the manufacturer's specified limits. Excessive pressure or temperature can lead to premature wear, so regular checks will help you avoid costly replacements in the long run. By following these maintenance tips, you can significantly extend the lifespan of your three-way ball valve and enhance its reliability in your industrial processes.