Choosing the right Steering Cylinder is crucial for vehicle performance. An optimal steering cylinder ensures both safety and precision during driving. According to a report by the International Automotive Steering Association (IASA), the global steering system market is expected to exceed $35 billion by 2025. This growth reflects increasing demands for advanced steering technologies.

Expert Richard Malone, a leading figure in automotive engineering, emphasizes, “The right steering cylinder can significantly enhance vehicle control.” Quality and compatibility are key factors to consider when selecting a steering cylinder. An ill-fitting component might compromise handling, leading to potentially dangerous situations on the road. Vehicle manufacturers often outline specifications to guide this selection process.

Moreover, it’s vital to analyze the specific needs based on vehicle type and driving conditions. For instance, off-road vehicles require more robust steering cylinders than standard cars. Many drivers overlook these factors, risking performance issues. Selecting the appropriate steering cylinder is not just a technical choice; it affects overall driving experience and safety. Choosing wisely can often be the difference between a smooth ride and a problem-laden journey.

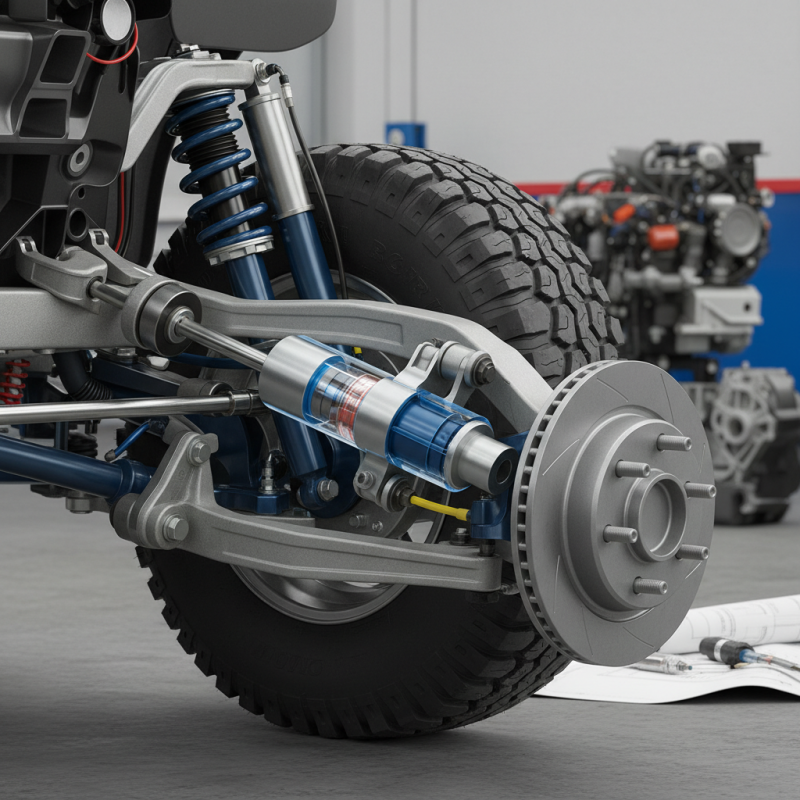

The steering cylinder plays a crucial role in a vehicle's steering system. It transforms the driver’s input into mechanical energy, ensuring that the vehicle responds correctly. This component influences how smoothly a vehicle turns and maneuvers. If the steering cylinder malfunctions, it can cause significant issues, such as poor handling or uneven tire wear.

Choosing the right steering cylinder isn't just about compatibility. The design and materials also matter. Vehicles come in various shapes and sizes, and their steering needs differ. A heavy truck needs a robust cylinder, while a compact car requires something more lightweight. Many people overlook these differences, leading to incorrect choices. It's essential to consider the vehicle's specifications and usage conditions.

Maintenance of the steering cylinder affects performance too. Dust, dirt, and moisture can lead to corrosion or leaks. Regular checks can prevent costly damages and ensure a safe driving experience. Yet, many drivers ignore these checks, often leading to regret later. Awareness and understanding of the steering cylinder can lead to better decision-making when choosing replacement parts.

When selecting the right steering cylinder, it's crucial to know the types available. Common types include hydraulic and electric steering cylinders. Hydraulic cylinders use fluid pressure to assist steering. This type is often seen in heavy-duty vehicles. Electric cylinders rely on motors to provide steering support. They are growing in popularity due to better fuel efficiency.

Understanding your vehicle's requirements is vital. For smaller cars, electric steering may be sufficient. However, larger vehicles may require the robustness of hydraulic systems. Each type offers unique advantages and challenges. An electric system may sometimes lack the feedback of a hydraulic one. This could affect driving confidence.

Consider consulting with professionals when choosing. They can help clarify the best option for your needs. Each vehicle is different. There's no one-size-fits-all solution. Reflecting on your driving style and needs can lead to better decisions. Sometimes, what seems perfect may not fit your long-term goals.

Choosing the right steering cylinder is critical for vehicle performance. Several key factors come into play. One major aspect is the vehicle's weight. Heavier vehicles require robust cylinders to ensure proper steering response. According to a recent industry report, steering systems should have a strength-to-weight ratio of at least 3:1. This ensures optimized performance and safety.

Another consideration is the environment in which the vehicle operates. For instance, off-road vehicles often demand specialized cylinders. These must endure harsher conditions, such as extreme shocks and moisture exposure. A study highlighted that about 30% of steering system failures in off-road scenarios stem from inadequate cylinder durability. Choosing materials designed for such environments is crucial.

Next, assess the steering angle and responsiveness. The cylinder's design should match the vehicle's turning requirements. Certain designs enhance maneuverability but may sacrifice stability. Reflecting on your needs helps find a balance. Many users overlook this when selecting steering components, leading to potential issues later. Each factor plays a role that can significantly impact overall driving experience.

When selecting a steering cylinder, assessing compatibility with your vehicle's specifications is crucial. The right fit ensures safety and performance. A 2022 industry report indicates that over 30% of steering issues stem from incompatible components. Choosing the wrong cylinder can lead to failures or malfunction, posing serious risks.

Check the specifications thoroughly. Look at the vehicle's weight, engine size, and intended use. The steering cylinder must match the hydraulic pressure requirements. Many vehicles require specific dimensions and mounting points. A mismatch in size can lead to excessive wear or system failure.

Keep in mind, not all cylinders are created equal. Variances in design and material can affect performance. Some might seem to fit but fall short on durability. Reports show that nearly 20% of steering system replacements are due to these issues. Always verify compatibility to avoid unnecessary repairs and ensure a safe driving experience.

When selecting a steering cylinder, proper maintenance is crucial for optimal performance. Simple checks can prevent extensive damage. Checking fluid levels regularly is a good start. Industry reports indicate that over 30% of steering issues stem from inadequate fluid maintenance. Low fluid can lead to system failure, affecting steering response.

Installation is just as important as maintenance. A correctly installed steering cylinder ensures safety. Improper alignment can lead to uneven wear. This could result in costly repairs down the line. Studies show that 15% of vehicle accidents involve steering-related failures. Using the right tools and techniques during installation can mitigate these risks.

However, many vehicle owners overlook these aspects. They often face unexpected issues after installation. Regular checks and correct installation reduce the likelihood of these problems. Emphasizing routine maintenance not only prolongs the steering cylinder's life but also ensures a safer driving experience. Remember, a small oversight can lead to significant consequences.

| Dimension | Measurement | Material | Weight (lbs) | Pressure Rating (psi) |

|---|---|---|---|---|

| Bore Diameter | 2.5 inches | Steel | 15 | 1500 |

| Rod Diameter | 1 inch | Aluminum | 10 | 2000 |

| Overall Length | 20 inches | Cast Iron | 25 | 1200 |

| Stroke Length | 12 inches | Composite | 5 | 3000 |

| Mounting Type | Cross-Mount | Steel | 12 | 1800 |