In the evolving landscape of industrial manufacturing, the importance of selecting the right components is paramount, particularly when it comes to critical flow management devices like the Three Way Ball Valve.

According to a report by MarketsandMarkets, the global ball valve market is expected to reach $8.7 billion by 2025, growing at a CAGR of 5.5% during the forecast period. This growth underscores the vital role that certifications play in ensuring product quality and compliance with international standards.

According to a report by MarketsandMarkets, the global ball valve market is expected to reach $8.7 billion by 2025, growing at a CAGR of 5.5% during the forecast period. This growth underscores the vital role that certifications play in ensuring product quality and compliance with international standards.

As companies expand their import and export activities, understanding the nuances of certification requirements becomes essential for making informed choices about the best Three Way Ball Valves. This blog will delve into the certification complexities and offer guidance to industry stakeholders, helping them navigate this intricate landscape while ensuring compliance and enhancing operational efficiency.

Import and export certifications play a crucial role in the selection of industrial valves, particularly for applications involving three-way ball valves. These certifications ensure that the products meet international quality standards, thus facilitating smoother trade processes. According to a report by MarketsandMarkets, the global valve market is projected to grow from USD 78.0 billion in 2021 to USD 109.2 billion by 2026, underscoring the importance of compliance in driving market growth. Having valid certifications not only enhances reliability but also assures buyers of the durability and efficiency of the valves they are investing in.

Import and export certifications play a crucial role in the selection of industrial valves, particularly for applications involving three-way ball valves. These certifications ensure that the products meet international quality standards, thus facilitating smoother trade processes. According to a report by MarketsandMarkets, the global valve market is projected to grow from USD 78.0 billion in 2021 to USD 109.2 billion by 2026, underscoring the importance of compliance in driving market growth. Having valid certifications not only enhances reliability but also assures buyers of the durability and efficiency of the valves they are investing in.

When choosing a three-way ball valve, it is essential to understand the different certifications that may apply, such as ISO 9001 for quality management systems or API 598 for valve testing. These certifications can guarantee that the valves operate correctly under specified conditions.

Tips: Always verify the certification status of the supplier before placing orders. Additionally, consider requesting detailed documentation on the testing processes used for the valves to ensure they align with industry standards. This proactive approach can save costs and improve overall project outcomes by minimizing the likelihood of failures.

When selecting three-way ball valves, understanding the key certifications can significantly impact performance and safety, particularly in sensitive applications like food and beverage processing. Notably, NSF certification is crucial for ensuring that valves meet stringent standards for potable water. For instance, recent announcements highlighted certifications for various valve types, reaffirming the demand for NSF-approved solutions in the industry.

It's essential for manufacturers to prioritize certifications that guarantee compliance with health and safety regulations. Recent reports indicate that valves certified under NSF 61 are vital for preventing lead leaching into drinking water, a growing concern as new brass valve installations may exceed lead limits. Therefore, the selection of certified materials not only aids in maintaining safety but also ensures product longevity and effectiveness.

**Tips:** Ensure you verify the certifications of any valves considered for your application. Look for NSF or other relevant certifications if your process involves drinking water. Regularly check for updates on standards as regulatory frameworks can evolve, impacting your valve choices.

When it comes to selecting the best three-way ball valves for import and export, understanding the quality standards in Chinese manufacturing is crucial. According to a 2022 report from the China National Quality Supervision and Inspection Center, nearly 30% of exported industrial valves did not meet international quality standards. This raises significant concerns for global buyers who rely on the dependability and performance of these products. As a result, leveraging quality certifications such as ISO 9001 and the European Union's CE marking has become vital in ensuring that manufacturers comply with both local and international standards.

Moreover, the recent industry analysis published by the International Trade Administration highlights that over 60% of buyers conduct rigorous audits of their Chinese suppliers to verify compliance with quality standards and certifications. This emphasis on quality not only helps safeguard against potential market entry barriers but also enhances the overall reliability of three-way ball valves across various applications. Investing time in verifying certifications and analyzing manufacturer quality can lead to better purchasing decisions, ultimately benefiting end-users with products that result in reduced operational risks.

When selecting three-way ball valves, understanding the impact of certifications on performance is critical. Certifications serve as a guarantee of quality, safety, and reliability, ensuring that the valves meet stringent industry standards. For instance, valves that comply with ISO 9001 standards exhibit enhanced performance and longevity, which are vital in applications involving high pressure and temperature variations. According to a recent technical report, valves that are certified to meet ANSI standards show a 25% increase in operational efficiency due to their robust design and manufacturing processes.

Tips: Always check for specific certifications related to your application. For example, if the valve is to be used in a food processing environment, look for FDA-compliant models to ensure safety and quality.

In addition to regulatory certifications, performance metrics such as flow coefficient (Cv) and pressure drop characteristics are crucial in evaluating the suitability of a valve. Research indicates that three-way ball valves with higher Cv values can significantly reduce energy costs, as they ensure optimal flow rates while minimizing turbulence. By prioritizing certified options, engineers and procurement professionals can avoid costly downtimes and enhance system reliability.

Tips: Conduct comparative studies on different brands and their certified models to understand their performance metrics better before making a purchase.

In today's global marketplace, understanding certification requirements is crucial for businesses engaged in the import and export of industrial valves. Compliance with international trade regulations not only safeguards against legal repercussions but also enhances brand reputation. As various countries implement stringent regulations, navigating these requirements can be challenging. Companies must develop effective strategies that include staying updated on mandatory certifications, technical regulations, and consumer protection standards relevant to their industry.

Recent discussions among industry leaders at events like the Valve World Americas Expo underline the importance of strategic dialogue in addressing compliance challenges. With the evolving landscape of international trade, including the shifting dynamics in U.S.-China relations and India's ascending role in global competitiveness, staying informed and adaptable is essential. By leveraging insights from industry events and aligning with best practices, businesses can ensure they meet certification demands, thus facilitating smoother international transactions and enhancing their competitiveness in the valve market.

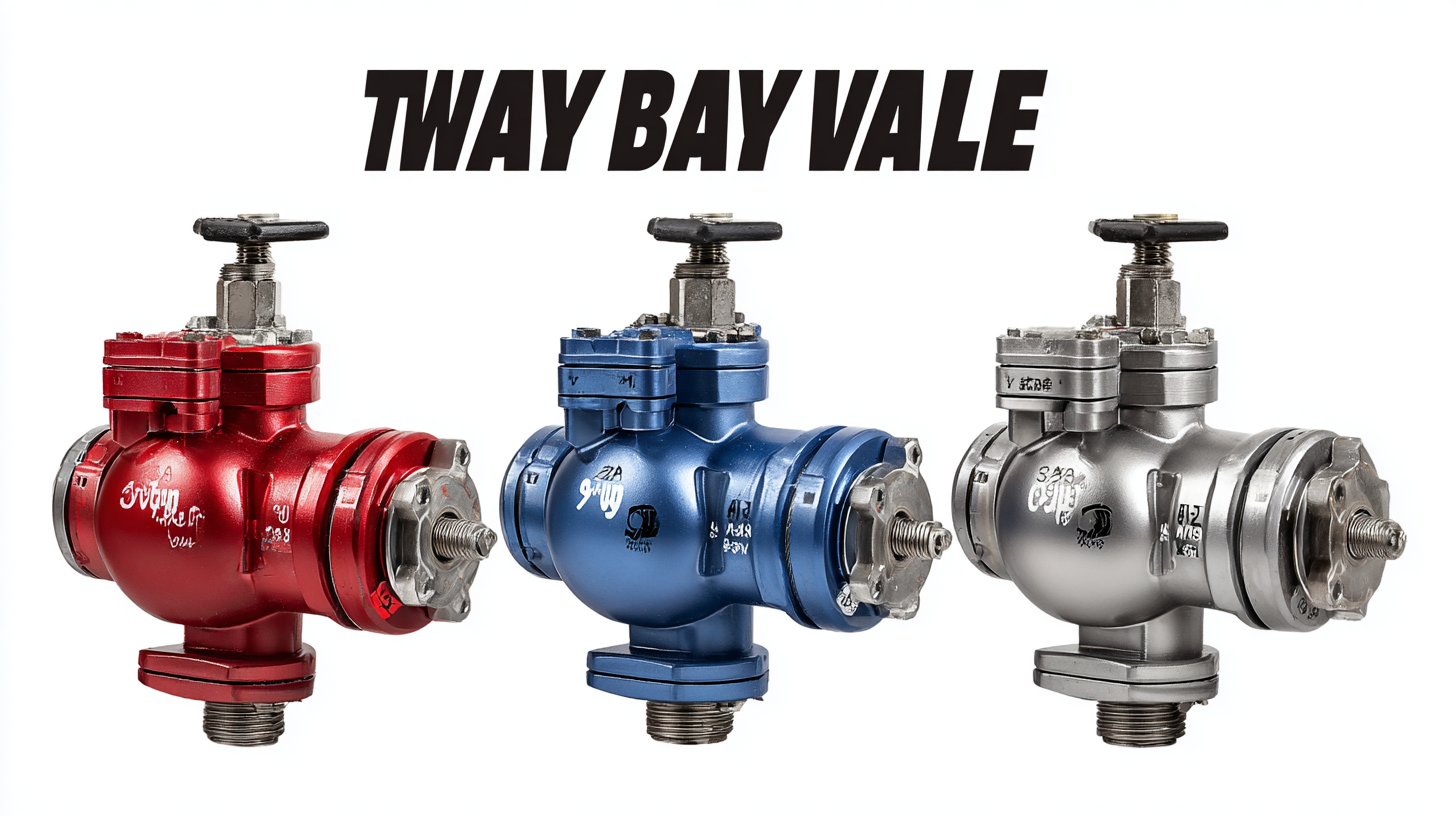

This chart illustrates the compliance levels of various certifications required for international trade of three way ball valves. Understanding these certifications helps manufacturers select the best products while ensuring compliance with international standards.